Mixed Laminate Multilayer PCBs

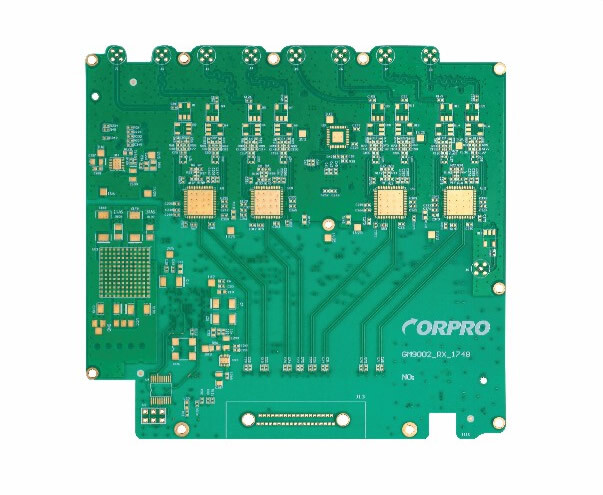

Consisting of multiple laminates and differing dielectric constants, this multilayer (displayed above) is a mixed-dielectric printed circuit board.

Mixed Laminate Multilayer PCBs

Mixed laminate multilayer PCBs are ideal for complex and high-speed circuit designs that require different dielectric constants. They are composed of multiple layers of different laminates, allowing for precise control of impedance, signal integrity, and heat dissipation. The different layers of mixed laminate multilayer PCBs can be interconnected using vias and buried vias, providing a high degree of routing flexibility.

Feature | Technical specification |

|---|---|

Number of layers | 4 – 16 layers |

Technology highlights | special materials, laminating ofmixed medium, fine lines |

Materials | FR4, Rogers4350B |

Profile method | punching, rout |

Copper weights (finished) | 18 μm – 70 μm |

Minimum track and gap | 0.075 mm / 0.075 mm |

PCB thickness | 0.05 mm – 3.0 mm |

Maxmimum dimensions | 450mm x 610mm |

Surface finishes available | OSP, ENIG, Immersion tin, Electrolytic gold, Gold fingers |

Why SprintPCB can Provide the most

competitive PCBs

Under the long-term strategic cooperation agreement with laminate supplier , the price we get is 10% cheaper than most competitors

PCB Inner / outer layers fab with LDI equipment, the automatic production reduce our labor cost 5%

Lean manufacturing increases product yield

About SprintPCB

We can provide competitive prices and guarantee the quality requirements of customers without excess quality. Our technical level can meet most of the industrial control and consumer products.

Quality Assurance System

SprintPCB has established a rigorous quality assurance system that spans every stage from customer requirements to product delivery, ensuring the fulfillment of high standards of customer requirements.

Audit

Specifically for products with special requirements, the company has an Advanced Product Quality Planning (APQP) team, which conducts Failure Mode and Effects Analysis (FMEA) to thoroughly study potential failure modes and develop proactive countermeasures to ensure product quality. Developing control plans and implementing Statistical Process Control (SPC) are key steps in preventing potential failures. In addition, measurement instruments undergo Measurement System Analysis (MSA) certification to ensure measurement accuracy. For cases requiring production approval, production part approval process (PPAP) documents are provided to ensure production confirmation.

Inspection

Quality assurance covers incoming, in-process, and final inspections, as well as product review. Customer-provided data and manufacturing instructions undergo rigorous review, and raw materials are strictly controlled. During production, operators conduct self-inspections and collaborate with QC for sampling inspections. The laboratory inspects process parameters and performance. Finished products undergo 100% electrical performance testing and full inspection for appearance, with sampling inspection for appearance and dimensions to ensure product perfection. Directed inspections for specific projects are conducted based on customer requirements.

Manufacturing Equipment at SprintPCB

SprintPCB operate with most advance equipment in the industry to provide efficient production and high quality products with value added to our partners

Trusted by innovators since 2007

In the race to build tomorrow, SprintPCB engineers and PCB designers continually patent new technologies,

crossing design barriers—to help innovators bring new products to market.

"I am extremely satisfied with the quality of the PCBs you manufacture. The solder pads on each board are very smooth and the connections are very strong. I have worked with other manufacturers before, but the quality was always subpar. Since switching to SprintPCB, the quality of my projects has significantly improved. Thank you for your outstanding manufacturing process!"

- John Smith

Get High-Quality PCBs or PCBA at a Fraction of the Cost

Why Pay More for PCB Manufacturing?

Partner with Us for the Best Prices!

FAQ about Mixed Laminate Multilayer PCBs

A Mixed Laminate Multilayer PCB is a type of printed circuit board that combines multiple layers of different materials in its laminate structure, providing improved electrical and mechanical performance.

The advantages of Mixed Laminate Multilayer PCBs include improved thermal management, increased electrical performance, reduced weight and improved dimensional stability.

Mixed Laminate Multilayer PCBs are manufactured by laminating layers of different materials such as metal-based substrates, ceramic-based materials, and FR-4, and then drilling and plating vias to interconnect the layers.

Mixed Laminate Multilayer PCBs are widely used in demanding applications such as telecommunications, industrial controls, medical devices, and military and aerospace systems.

CONTACT US

We would love to respond to your queries and help you succeed.

During our business Hours: 9:00~18:00