1. High Reliability

Temperature Resistance: Automotive PCBs must perform reliably across a wide temperature range, from -40°C to +150°C. This requirement is essential for maintaining stability in diverse environments, whether in cold climates or under the hood of a vehicle where temperatures soar.

Shock and Vibration Resistance: Vehicles are constantly subjected to vibrations and shocks during operation. Automotive PCBs must exhibit high vibration resistance to ensure stable connections of electronic components, avoiding failures that could compromise vehicle safety.

Longevity: The lifespan of an automotive PCB is designed to match the longevity of the vehicle itself. This means the PCB must function effectively over many years, even in harsh environments, making durability a key factor.

2. Superior Electrical Performance

High Signal Integrity: In automotive electronics, maintaining signal integrity is paramount, especially in high-frequency applications. Ensuring that signals are transmitted without interference is critical for the proper functioning of advanced automotive systems.

Low Electromagnetic Interference (EMI) and High Electromagnetic Compatibility (EMC): To prevent interference between various electronic systems within the vehicle, Automotive PCBs must minimize EMI and ensure high EMC. This ensures that all electronic modules in the vehicle operate without disrupting each other, contributing to overall system reliability.

3. Environmental Adaptability

Moisture and Corrosion Resistance: Automotive PCBs need to withstand exposure to moisture, salt spray, and chemical corrosion, conditions often encountered in vehicles. This is crucial for maintaining the PCB’s performance and preventing damage over time.

High Voltage and Current Handling: With the rise of electric vehicles, Automotive PCBs are increasingly required to handle high voltage and current. These PCBs must be designed to manage these demands safely and efficiently, ensuring the reliable operation of the vehicle's electrical systems.

4. Mechanical Strength

High Mechanical Strength: Automotive PCBs must endure significant mechanical stress and physical impacts during both installation and operation. A robust mechanical structure is vital for the PCB to maintain its integrity and performance throughout the vehicle's life.

5. Miniaturization and High Density

Miniaturization: As automotive electronics become more complex, there is a growing need for PCBs to be compact, integrating more functions into a smaller footprint. This trend towards miniaturization helps save space within the vehicle’s electronic systems.

High-Density Interconnects: To accommodate the increasing complexity of automotive electronics, Automotive PCBs must support high-density interconnections. This capability enhances the integration of sophisticated circuits, improving overall system performance.

6. Compliance with Automotive Standards and Certifications

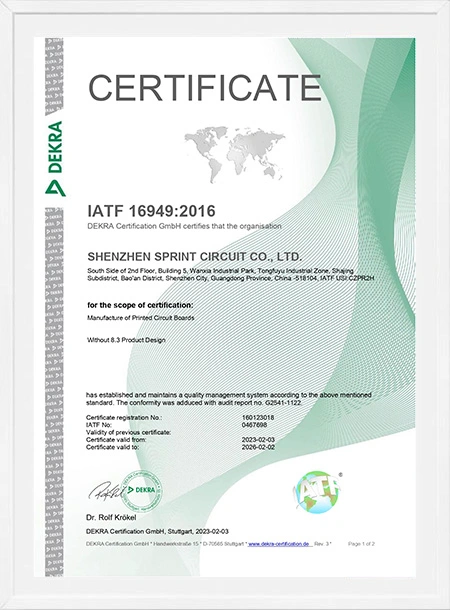

IATF 16949 Compliance: Automotive PCBs must be manufactured in compliance with the IATF 16949 quality management system standard. This certification ensures that the manufacturing process adheres to the strict international standards required for automotive applications.

IPC Class 3 Compliance: Meeting IPC Class 3 standards is crucial for Automotive PCBs, as these standards guarantee the highest levels of reliability and performance. PCBs that comply with IPC Class 3 are designed for critical applications where failure is not an option.

At SprintPCB, we excel in delivering Automotive PCBs that embody these critical characteristics. With advanced manufacturing capabilities, rigorous testing, and a focus on innovation, SprintPCB stands out as a reliable and high-performance Automotive PCB manufacturer.

Whether you need high-frequency PCBs, multilayer designs, or robust rigid-flex solutions, SprintPCB offers expertise and quality that you can rely on for your automotive applications. Our PCBs are built to withstand the toughest conditions, ensuring that your electronic systems perform flawlessly, even in the most demanding environments.