What is a high-frequency PCB?

High-frequency PCBs are specifically designed to handle high-frequency signals, typically those above 1 GHz, and microwave frequencies ranging from 300 MHz to 300 GHz. These boards have special requirements in terms of material selection, design layout, and manufacturing processes to ensure efficient signal transmission while minimizing signal loss and interference.

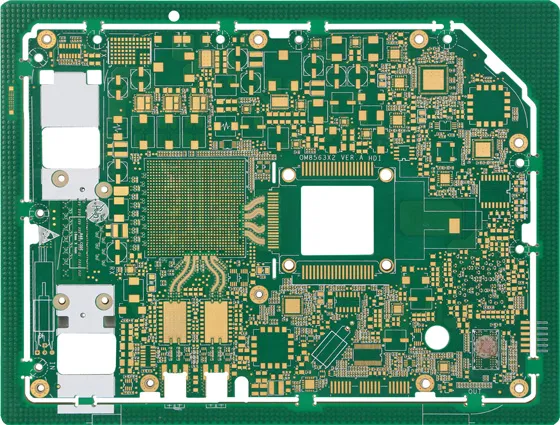

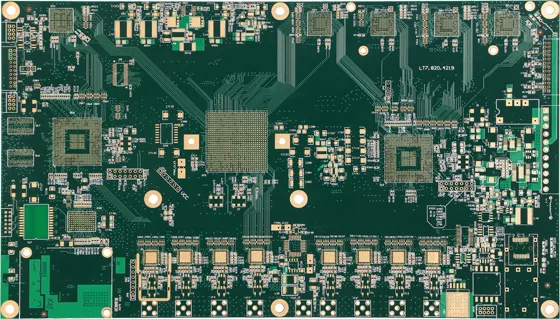

SprintPCB's high-frequency PCB process capabilities

Advantages of High-Frequency PCBs

High Efficiency

High-frequency PCBs use low dielectric constant materials, reducing signal transmission loss and improving transmission efficiency. SprintPCB leverages advanced material science to ensure minimal energy loss, enhancing overall performance.

High-Speed Transmission

Special materials ensure small dielectric constants, achieving faster transmission speeds and stable PCB operation. SprintPCB's expertise in material selection guarantees optimal signal integrity and high-speed data transfer for various applications.

Broad Adaptability

Suitable for various industries requiring precise heating, high-frequency PCBs achieve targeted and localized heating. SprintPCB's innovative design and manufacturing processes enable these PCBs to meet the specific needs of sectors like telecommunications, aerospace, and medical devices.

Environmental Resistance

With extremely low water absorption, high-frequency PCBs adapt well to humid environments and resist chemical corrosion, high temperatures, and have high peel strength. SprintPCB's rigorous quality control ensures that their high-frequency PCBs maintain reliability and durability in challenging environmental conditions.

Albee

Marketing Director

Efficiency from profession

Quality in priority

Distinguishing Ordinary FR-4 Materials from High-Frequency Materials

Ordinary boards use cotton fiber paper as the material, while high-frequency boards use alkali-free glass cloth. High-frequency boards are typically pressed from FR-4 glass fiber boards, featuring a uniform and bright color throughout the board. Due to increased density, high-frequency boards are heavier compared to low-frequency boards.

Low-frequency boards are often made from lower-end materials such as paper-based, composite-based, epoxy-based, and FR-4 glass fiber boards. Paper-based and composite-based boards have lower overall density, with consistent color on the back, but lack glass fiber cloth texture inside. Epoxy boards have varying color shades on the back, and scraping the fracture with a tool easily reveals off-white powder. FR-4 pieced boards, made from FR-4 glass fiber cloth scraps, exhibit large stripes on the back.

Characteristics of High-Frequency PCBs

High-Frequency Handling

Capable of handling GHz-level high-frequency signals, high-frequency PCBs meet the demands for high-speed data transmission and complex signal processing.

Low Loss

By using low-loss materials and structural designs, high-frequency PCBs minimize energy loss during signal transmission, enhancing transmission efficiency.

EMI Compatibility

With proper layout and grounding designs, high-frequency PCBs reduce electromagnetic interference and crosstalk, ensuring stable signal transmission.

High-Precision Manufacturing

The manufacturing process of high-frequency PCBs requires high-precision equipment and techniques to ensure the accuracy and consistency of the circuitry.

Application areas of high-frequency PCBs

Aerospace

In aerospace applications, high-frequency PCBs are indispensable in navigation, communication, and radar systems due to their superior performance and reliability.

Defense and Security

In military applications, high-frequency PCBs are widely used in electronic warfare, intelligence gathering, and weapon guidance systems, ensuring national security.

Medical Equipment

Advanced medical imaging equipment, such as MRI and CT scanners, rely on high-frequency technology to produce high-resolution images, which are essential for accurate diagnoses.

Communication Systems

High-frequency PCBs are crucial in satellite communication, 5G/6G mobile communication, and radar systems, supporting high-speed data transmission and precise signal processing.

Material Selection for High-Frequency PCBs

PTFE (Polytetrafluoroethylene) Materials

PPO/Ceramic Composite Materials

FR-4 Materials